class ii division 2 group g

Atmospheres containing combustible dusts not included in Group E or Group F including flour grain wood plastic and chemicals. Any grounding provisions must be in the main conduit box.

Practical Guidelines For Determining Electrical Area Classification

Note that the dust must be present in.

. The USA NEC States for Motors and Generators. Class II Div II receps in cabinet shops Ive been reading a lot on article 502-115 502-145 and speaking to the local authorities on the requirement for receptacles around wood working equipment. Just as in Class I Division 1 and 2 the subdivision of Class II into Divisions 1 and 2 identifies the likelihood that there will be an explosion hazard.

Zone 2 Group IIA. Certified for Class II Division 2 Groups F and G. D1xB2 range - Class I II Division 1 Zone 1 21 Xenon strobes and LED beacons.

Generally these dusts have the highest thermal insulating characteristics. Class II Division 2. To be considered a dust the combustible material must exist as a finely divided solid of 420 microns 0420 mm or less.

A major safety concern in all workplaces is the occurrence of fires and explosions. Class I Division 2 Group D. Division 2 involves a normal atmosphere that is non-combustible but can change due to an accident or equipment malfunction.

Motor accessories must be non-sparking or approved for Explosion Proof XP duty. NEC Zone 1. Raceways permitted as a wiring method in Class II Division 2 locations include _____.

Electrical equipment can and does cause fires andor explosions in certain atmospheres. NEC Class III Divisions 1 2. Would be acceptable for a Class II Division 2 Group FG hazardous area.

NEMA Type 9 enclosures dust ignitionproof are also accepted Reading the above it would appear that a NEMA4 enclsoure and operators lights etc. Class II Group F G locations are atmospheres containing dust such as F Carbon Black coal or Coke Dust G Flour Starch or Grain Dusts. CLASS II DUST DIVISION 1 DIVISION 2 GROUP E Metal Dusts GROUP F Carbon-based Dusts GROUP G Non-conductive Dusts.

They are not electrically conductive. NEC Class II Division 2 Groups F G. What is accepted in the USA.

Industrial Vacuum Dry Combustible Powders Pickup 115V. NEC Class II Divisions 1 2 Groups F G. NEC Zone 1 Group IIA.

Class II Division 2 is where. I recognize that temperature limitation will always apply however dust accumulations are not permitted in a Division 2 environment. NEC Class II Divisions 1 2 Groups E F G.

In Class II Div. ClassDivision Hazardous Location 33 Introduction A major safety concern in industrial plants is the occurrence of fires and explosions. Class II Group G.

Choose from our selection of CSA certified Class 2 group G switches in a wide range of styles and sizes. Choose from our selection of Class II Division 2Group G switches in a wide range of styles and sizes. Class II Division 2 Archives - Ruwac USA.

These fine particles can float and collect on equipment in the surrounding areas. If the dust removal system sufficiently eliminates the wood flour the shop area may even be considered an unclassified space based on National Fire Protection Association NFPA 499 Recommended Practice for the Classification of Combustible Dusts. A Class II Division 2 location is a location in which combustible dust due to abnormal operations may be present in the air in quantities sufficient to.

102 Amps 115 V 60 Hz AC. Group F is for carbonaceous dust like charcoal coal and carbon black. Dry pickup03 micron HEPA filter.

Such a dust will pass through a No. EXPLOSION PROOF PRODUCTS1 Contains Explosion Ex d SERIES 70 ELECTRIC ACTUATOR NEC CLASS I DIV 1 CD. Class II Group G.

As required by Underwriters Laboratories and Canadian Standards. A RMC and IMC b EMT c ENT d a or b. Class II Division 1 2 E Division 1 only Metal dusts such as magnesium Division 1 only F Carbonaceous dusts such as carbon charcoal G.

Motors suitable for Class II Groups F G Division 2 are available in TEFC TEFC-XT TEBC TEAAC and TEWAC only. E2x non-sparking devices now for Class I. No other aspect of safety receives more attention in the form of codes and standards.

Combustible fibres and flyings. The specific hazardous materials within each group and their automatic ignition temperatures can be found in Article 500 of the National Electrical Code and in NFPA 497. For example the grain silo noted earlier is a Class II Division I Group G area.

NEC Class II Division 2 Groups F G. 1 locations provide electrical controls eg switches breakers control transformers and resistors with enclosures identified for use in the location 502115 502120. No other aspect of industrial safety receives more attention in the form of codes standards technical papers and engineering design.

NEMA and UL designations for dusttight equipment are Types 3 3S 4 4X 6 6P 12 12K and 13. 2 provide this equipment with enclosures that are dusttight or identified for the location 502115 502120. NEC Group G refers to an area that.

Combustible dusts not in group E or F. NEC Class II Divisions 1 2 Groups E F G. In stock and ready to ship.

In stock and ready to ship. Ambient may not exceed 60C make addition for higher than 40C ambient as required. The correct answer is.

TEFC in Class 2 Div 2 Group G. Class II Division 1 Groups E F or G as defined in NFPA 70. NEC Class III Divisions 1 2.

In terms of the CEC system Division 1 relates only to Class I and Division 2 relates only to Class II and can still be used for the maintenance and repair of existing facilities. Groups E F and G are for dusts and flyings Class II or III. They are calling it Class II Div II group G My question is do I have to use explosion proof receptacle or do they make something more.

Protection Techniques for Hazardous Areas. Aolalde Electrical 24 Jan 05 1643. C Class II Locations.

Groups A B C and D are used for Class I environments Groups E F and G for Class II areas. Class II Division 1 is in an area where dust material is handled manufactured or used. Case the area would be categorized as a Class II Division 2 Group G.

Classes Divisions and Groups. I cannot find any reliable source to come out and specifically say that NEMA 12 or NEMA 4 enclosures are suitable for use in Class II Division 2 Group G environments. D a or b.

Article 502 covers the requirements for electrical and electronic equipment and wiring for all voltages in Class II Division 1 and 2 locations. Group G dusts include plastic dusts most chemical dusts and food-grain dusts. NEC Class II Divisions 1 2 Groups F G.

I cannot find any reliable source to come out and specifically say that NEMA 12 or NEMA 4 enclosures are suitable for use in Class II Division 2 Group G environments. In Class II Division 2 locations motors generators and other rotating electrical equipment shall be. See answer and applicable Code reference.

And Group G is for non-conductive dust like flour grain and plastic. If you r location is Class-II Division 2 not dust blanketed you are allowed to use TEFC motors. However any new construction must reference the newer International Electrotechnical Commission IEC Zone Classification.

Ex II 1 G Explosion protected Group 2 Category 1 Gas Ex ia IIC T4 Type ia Group 2C gases Temperature class 4 Ex nA II T3 X. Just as in Class I Division 1 and 2 the subdivision of Class II into Divisions 1 and 2 identifies the likelihood that there is an explosion hazard.

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Practical Guidelines For Determining Electrical Area Classification

Self Regulating Heating Cables Approved For Use In Hazardous Locations Briskheat

Ul And C Ul Hazardous Areas Certification For North America Ul

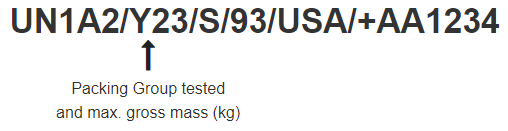

Packaging Your Dangerous Goods Federal Aviation Administration

Ul And C Ul Hazardous Areas Certification For North America Ul

Practical Guidelines For Determining Electrical Area Classification

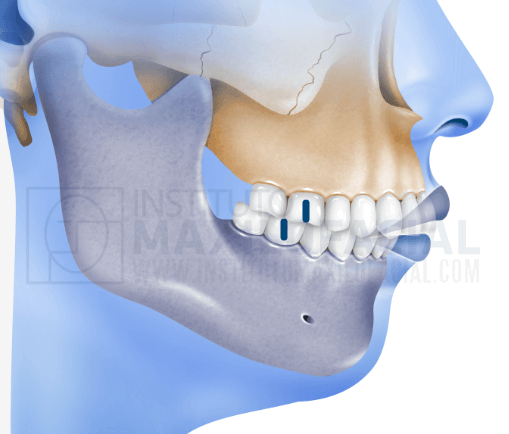

What Is A Class I Class Ii Or Class Iii Bite Instituto Maxilofacial

Practical Guidelines For Determining Electrical Area Classification

Practical Guidelines For Determining Electrical Area Classification

Military Unit Definition Facts Examples Britannica

Practical Guidelines For Determining Electrical Area Classification

Ul And C Ul Hazardous Areas Certification For North America Ul

The Best Headlamps For Hazardous Environments In 2021 Underwater Kinetics

Ul And C Ul Hazardous Areas Certification For North America Ul